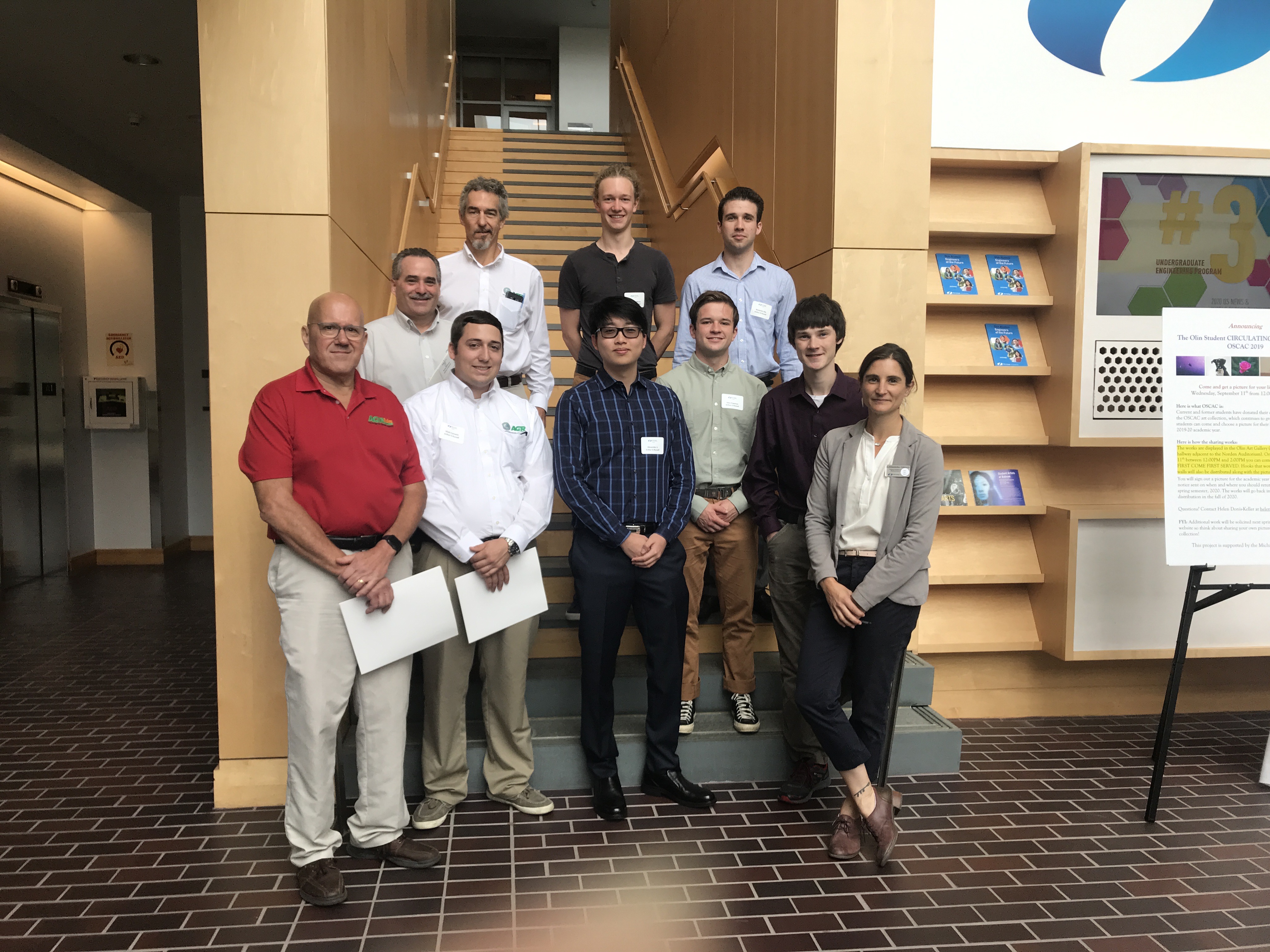

Arthur G. Russell 2019-2020

Faculty Advisor: Alessandra Ferzoco

Sponsor: Arthur G Russell

Multivariable Vibratory Test Platform

The Arthur G. Russell Company designs and delivers high-volume and ultra-high-volume assembly systems. An integral part of these systems is vibratory parts feeding. Because vibratory parts feeding is governed by chaotic and unpredictable dynamics, experimental testing and validation is necessary to build systems with optimized part feeding efficiency.

The Olin AGR SCOPE team designed and analyzed a vibratory test platform that can be configured to experimentally test multiple vibratory characteristics. They used computer simulations and physical sketch models to explore design possibilities, and explain why existing designs would fail to withstand the forces of the more powerful vibratory platforms needed to increase part feeding rate. The team did mathematical analysis and preliminary experiments on a proof-of-concept platform and actuation scheme to specify the physical parameters needed to drive their prototype. Through analysis and design iteration, they settled on a prototype that balances usability and trade-offs between a number of physical parameters. This tool will help the company’s R&D department test and optimize feeding characteristics quantitatively.

Faculty Advisor

Alessandra Ferzoco

Team Members

Walker Trelease

Alex Chapman

Rowan Sharman

Benjamin Lilly

Alexander Li

Project Poster

Summit Breakout Session